Fluidized beds are widely utilized in various industries and are key players in the shift towards renewable energy sources, as well as in the production of essential goods like food and drugs. However, due to the intricate nature of the processes occurring inside fluidized beds and the lack of effective measurement techniques, our understanding of these systems has remained limited. Addressing this challenge, researchers from Chalmers University of Technology in Sweden have developed a groundbreaking high-frequency radar technique that enables precise measurements of fluidized bed dynamics. This breakthrough has the potential to revolutionize processes across multiple industries, including energy conversion. The study detailing this technique has been published in the journal Fuel.

Fluidized bed combustion is a leading technology employed in thermal power plants worldwide. By converting solid fuels like biomass and waste into district heating and electricity, this technology plays a crucial role in the global energy landscape. Moreover, fluidization technology is fundamental to various other processes that are expected to contribute significantly to the transition towards sustainable energy systems. These processes encompass carbon capture, energy storage, hydrogen production, and the generation of other fossil-free fuels. However, the lack of a comprehensive understanding of fluidized bed dynamics has hindered the development and optimization of these processes.

Chalmers University of Technology researchers have now introduced a radar technique capable of characterizing the movement of solid particles within fluidized beds in great detail. This technique fills a critical gap in our measurement capabilities, which has impeded progress in fluidized bed-related processes. Fluidized beds already serve as the most efficient technology for converting solid biofuels into energy. This efficiency stems from the ability of solid particles to assume a liquid-like state, facilitating the homogeneous distribution of heat in the combustion chamber. In essence, fluidization technology involves blowing gas through a bed of small sand-like particles in a reactor, ensuring thorough mixing of the fuel, solid particles, and gas.

To achieve even higher efficiencies in fluidized bed processes, it is essential to comprehend and control the behavior of solid particles within the mixture. However, the reactor environment is often harsh, characterized by high temperatures, dirt, and corrosive substances. These conditions resemble a combination of a sandstorm and a wildfire, making it challenging to obtain measurements and hindering our understanding of the reactor’s internal dynamics.

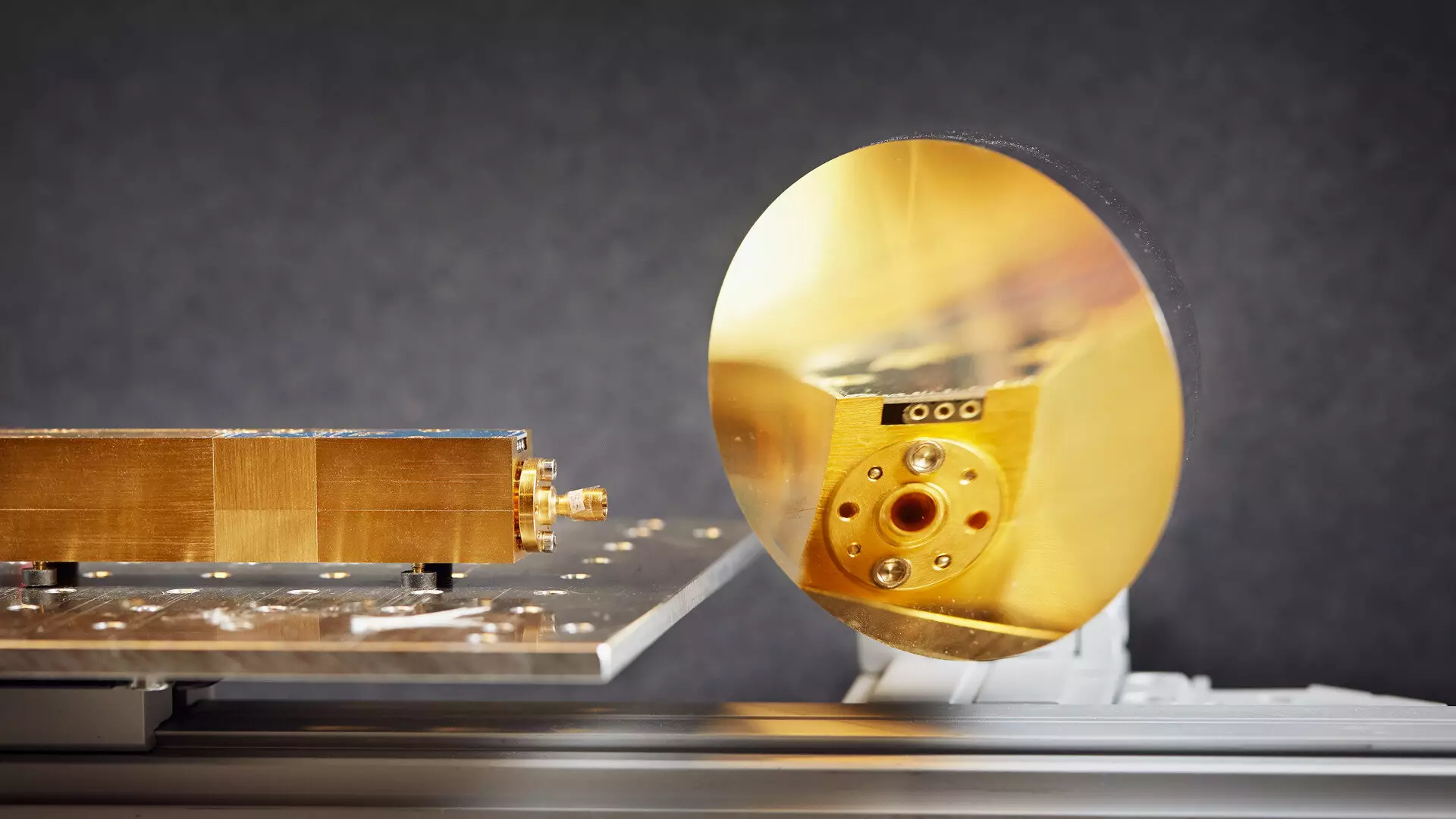

The Chalmers researchers have devised an innovative solution to this problem by developing an extremely high-frequency radar technique. This radar technique draws inspiration from pulse-Doppler radar, which is commonly used to track weather phenomena like rain or snow. Importantly, this study marks the first demonstration of the application of pulse-Doppler radar in the context of fluidized beds. This breakthrough is expected to catalyze the development of new and more efficient processes across multiple industries.

Diana Carolina Guío Pérez, a researcher in energy technology at Chalmers, emphasizes the potential impact of the high-frequency terahertz radar instrument developed in their study. This instrument has the capacity to revolutionize fluidized bed technology, enabling advancements in diverse industrial sectors ranging from energy conversion to food production and drug manufacturing. The study showcases one of the few applications of the pulse-Doppler radar technique at submillimeter wave frequencies and its inaugural use in fluidized bed measurements.

Traditional measurement techniques in fluidized beds typically suffer from low resolution, ambiguous results, or disturbances in the flow. In contrast, the high-frequency terahertz radar technique developed by the Chalmers researchers penetrates the reactor from the outside, allowing non-invasive measurements of particle behavior without disrupting the flow. This radar technique can simultaneously provide precise measurements of particle velocity and concentration, offering high temporal and spatial resolution. Consequently, even the slightest changes in the flow can be detected in real-time, enabling effective monitoring and control of industrial processes.

The researchers conducted a practical demonstration of their technique in a three-meter high circulating fluidized bed boiler, achieving measurement quality that significantly surpassed existing methods in the field. Marlene Bonmann, a post-doctoral researcher at the Terahertz and Millimeter Wave Laboratory at Chalmers, highlights the ability of their pulse-Doppler radar technique to measure particle distribution and velocity at frequencies up to 340 GHz. This level of detail has been sorely lacking in the field and holds potential for enhancing and scaling up process reactors. In the context of energy conversion, these advancements can also contribute to reducing the emissions of unwanted byproducts.

The knowledge gained through the use of high-frequency terahertz radar has the potential to revolutionize our understanding of solids flow in fluidized bed reactors and other solid handling units. By improving the operation and design of reactors in existing and emerging fluidized bed-based conversion processes, such as carbon capture, energy storage, and thermal cycling, this technique can open new frontiers in sustainable industrial practices. With the ability to precisely measure and comprehend fluidized bed dynamics, industries can unlock new levels of efficiency and pave the way for a greener future.

Leave a Reply